Kronospan OSB3 TAG board 2500x625x18 mm

- Pallet dimensions (length x width x height): 250x62,5

- Max. pallets per truckload: 36

- Boards per pallet: 39 boards

- Full specification

OSB (Oriented Strand Board), is a commonly used material in the construction industry. It consists of three layers of flat chips, laid under high pressure and temperature. Synthetic resins act as a binder, giving the board durability and strength. Characteristically, the chips in the outer layers are oriented along the longer edge, while in the inner layer they are arranged transversely.

The offer has been displayed in catalog mode.

Log in to go to shopping mode.

Pallet price: 367.77 € excl. VAT

This product is available in the following variants:

Dimensions:

Type of milling cutter:

Thickness:

Kronospan OSB Boards

OSB (Oriented Strand Board) is produced from long, flat strands of wood. The outer layers of the board have strands running parallel to the length, while the inner layers have strands running perpendicular. This unique construction provides excellent shape stability and high durability.

Advantages

Kronospan manufactures OSB boards in OSB/3 types. Importantly, OSB boards are produced using adhesives (synthetic resins) that are formaldehyde-free. This makes the boards highly ecological and environmentally friendly, with formaldehyde levels equivalent to natural wood. OSB boards exhibit excellent strength parameters, impact resistance, very good thermal and acoustic insulation, shape stability, and dimensional accuracy. They are an ideal wood-derived material for a wide range of applications in construction, furniture industry, packaging production, and automotive industry.

Technical and Industrial Applications:

- Temporary construction site fences

- Construction of utility buildings

- Production of construction site containers

- Exhibitions (trade show booths)

- Decoration, furniture elements, furniture frames

- Soft, for door panels

- Construction of sales and exhibition stands and podiums

- Billboard production

- Production of packaging, pallets, transport containers

- Meeting high technical requirements

- Warehouse management (shelves, partition walls, etc.)

- Material for repairs and reconstruction

Construction Applications:

- Structural material in frame construction

- For load-bearing floor and roof elements

- For walls and ceilings

- Construction of reinforcing external and internal walls

- For floors

- Production of floor joists

- As finishing boards on walls and ceilings

- For roof coverings and formwork

- For the superstructure of residential houses

- Temporary closing of openings in buildings

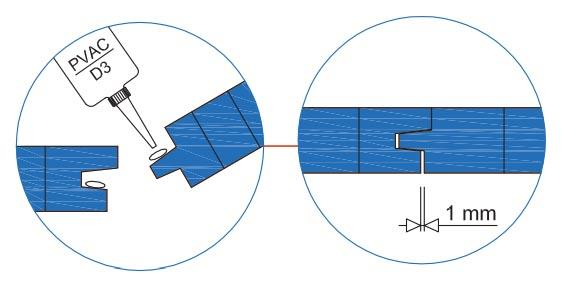

How to Connect Boards

OSB boards with tongue-and-grove (TAG) edges does not require additional auxiliary support, the boards interact with each other. All tongue and groove joints should be glued with a suitable adhesive, such as polyurethane-based or PVAC-D3, to further stiffen the structure and prevent cracking and breaking at joints.

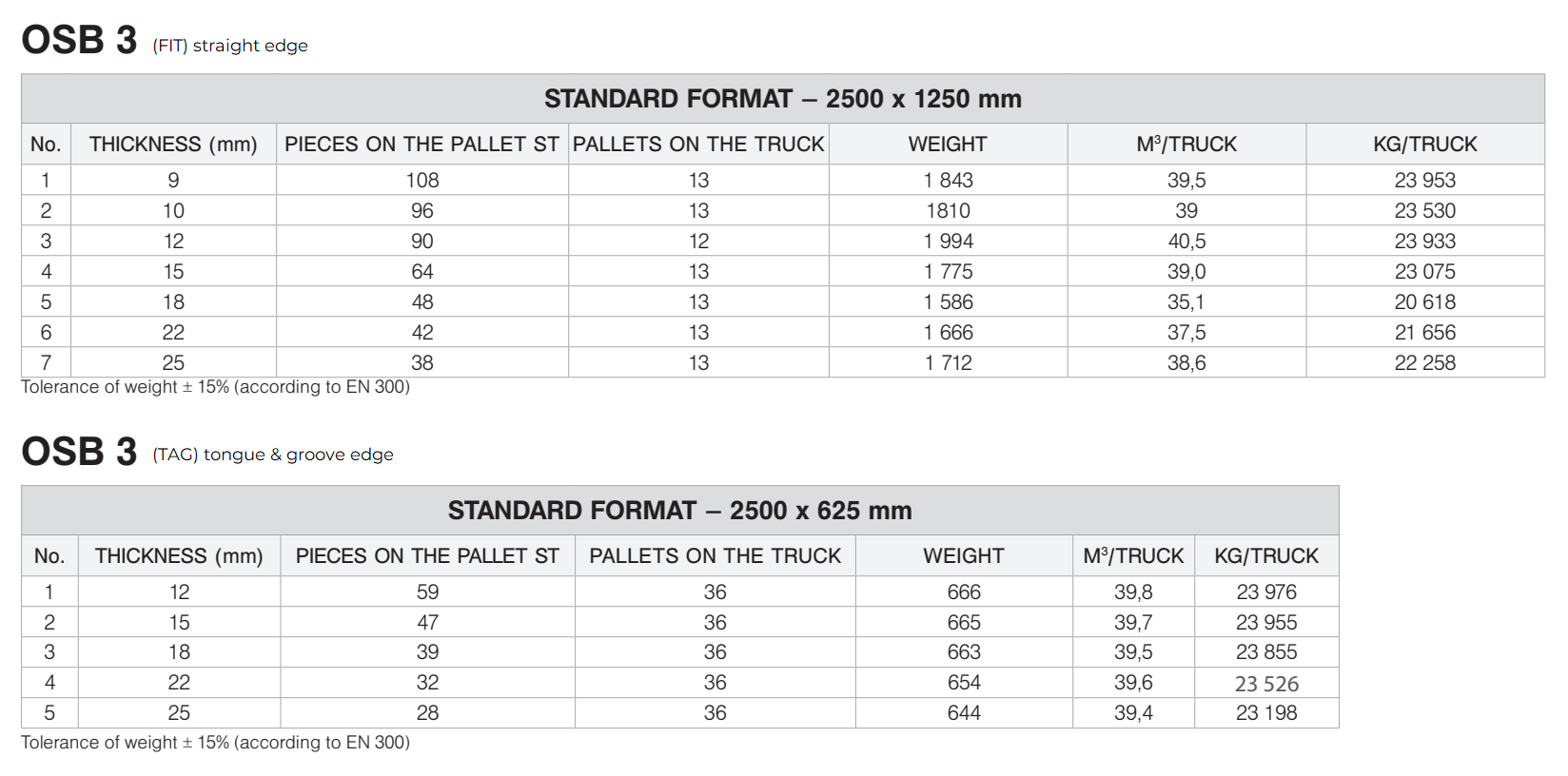

Logistics and packaging

STANDARDS

- ST_OSB/3LOFT_CPR_2023 - The panels are suitable for indoor use as structural elements in damp conditions,

- EN 13986:2004+A1:2015,

- According to the manufacturer's specifications 1583-PIT

- Oriented Strand Boards (OSB) EN 300

| Dimensions | 250 x 62.5 x 1.8 cm |

|---|

Technical specifications

| Manufacturer | Kronospan |

|---|---|

| Pallet dimensions (length x width x height) | 250x62,5 |

| Max. pallets per truckload | 36 |

| Boards per pallet | 39 boards |

| Weight per pallet | 663 kg |