RIGIPS 4PRO Hydro type H2 (GKBI) plasterboard 1200x2600x12,5 mm

- Pallet dimensions (length x width x height): 120x260

- Max. pallets per truckload: 14

- Boards per pallet: 62 boards

- Full specification

Type H2 gypsum board with impregnated PRO edges. 4PRO technology ensures smooth walls/ceilings, reducing work time and filler use. Crafted with PRO technology on all edges, it allows instant assembly, excludes cutting transverse joints, ensures joint smoothness, consistent strength/appearance, and significant savings in mass and time. Enables making longitudinal and transverse joints in one step, with thinner layer for full-surface mudding.

The offer has been displayed in catalog mode.

Log in to go to shopping mode.

Pallet price: 672.08 € excl. VAT

Lowest price from 30 days before discount: 10.84 €RIGIPS® 4PRO Hydro Plasterboard

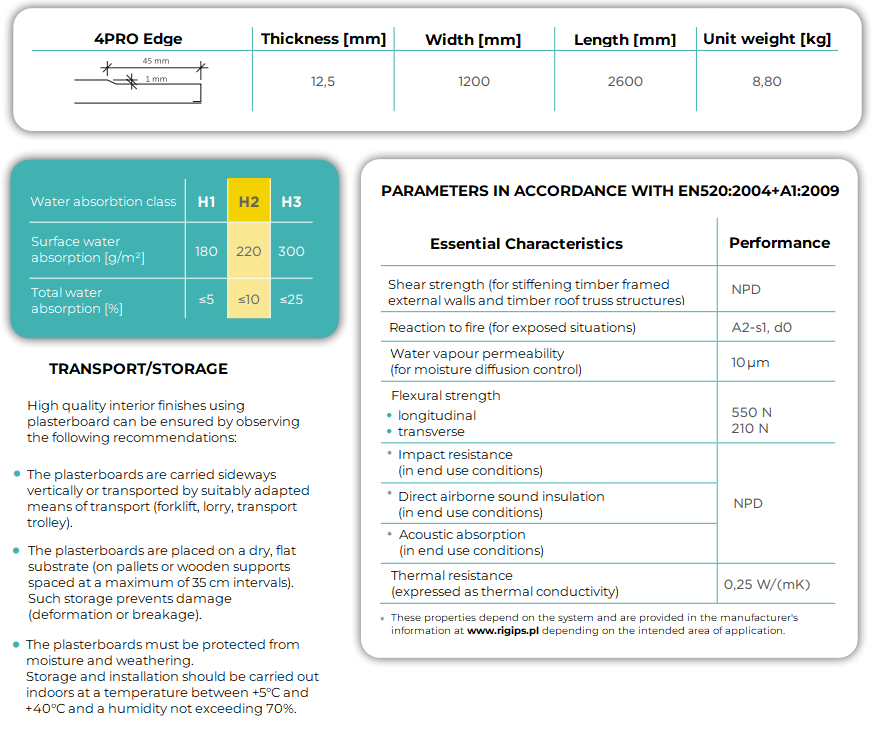

Type H2 (GKBI) impregnated plasterboard, 12,5 mm thick, with four flattened PRO edges.

The 4PRO™ technology is the only solution on the market that makes it possible to create walls/ceilings of the highest degree of smoothness, while shortening the work time and significantly reducing the use of filling compounds. The effect is achieved thanks to PRO technology on all 4 edges, allowing for instant assembly, eliminating the need for cutting transverse joints, ensuring no thickening at the joints, providing the same strength as longitudinal joints, the same appearance, great savings in mass and time, and the possibility of making longitudinal and transverse joints in one step. In the case of full-surface mudding, a much thinner layer of material is required.

Advantages of RIGIPS® 4PRO Hydro boards:

- Easy navigation on the board. The dots in the middle of the board make it easier to install the boards with the profile spacing of 60 cm, and the dotted lines placed in 1/3 and 2/3 of the board make it easier to install the boards with the profile spacing of 40 cm.

- 4PRO boards enable all joints, including transverse joints, to be made using the same technology. This results in: maximum strength, highest smoothness of finish, time and material savings.

- Quick and precise installation made possible by the printed measuring tape along the edge of the board.

- Small PRO edge depth (1 mm).

- Maximum strength of the joint between plasterboards thanks to optimum placement of the joint tape (less risk of cracks).

- 1-fold structural mudding of the joint between plasterboards with the use of a joint tape, due to imperceptible shrinkage of the binding and drying mass (low thickness of joint compound).

- Reduced consumption of joint compound needed to make a joint between plasterboards, resulting in savings in the costs of purchasing materials.

- Shorter time needed to achieve a ready joint due to faster drying of a thin layer of joint compound.

- Freedom of plasterboard installation using sheet metal screws (screws even 10 mm from the board edge).

- Easy control of planes created at the joint between two plasterboards.

- Intended for use in rooms where the relative humidity does not exceed 70% and periodically (for a maximum of 10 hours per day) with increased relative humidity of up to 85%.

Application

- Wall claddings (including "dry plaster")

- Partition walls

- Suspended ceilings

- Ceiling linings

Particularly recommended in bathrooms, toilets, kitchens in single and multi-family homes.

Technical parameters

| Dimensions | 260 x 120 x 1.2 cm |

|---|

Technical specifications

| Manufacturer | Rigips |

|---|---|

| Pallet dimensions (length x width x height) | 120x260 |

| Max. pallets per truckload | 14 |

| Boards per pallet | 62 boards |